#502

LIFE IN THE FAST LANE

12 Jun 2017 By David Fuhrmann-Lim

One Man’s Quest to Make 20-Year-Old Rum in Just Six Days. What Kind of Sorcery is This? Read On.

By Wayne Curtis

From the outside, the Lost Spirits Distillery is just another boxy, early-20th-century building along the frayed edge of downtown Los Angeles. At first the inside appears similarly uninspired: deep and unfinished, littered with cardboard boxes, plumbing fittings, spools of wire, inscrutable items made of copper, a forklift. The usual crap.

But what’s this then? A heavy black curtain bisects the industrial space from floor to ceiling, nearly from the front door to the back. Bryan Davis, the distillery’s founder and co-owner, pulls aside some folds and beckons me in.

It’s dark; my eyes adjust slowly. I’ve stumbled into a nighttime clearing deep in a tropical jungle—lush foliage and flowering vines lit by dozens of flickering candle lanterns. Are those crickets and cicadas and an occasional Jurassic Park bellow I hear? Yes. Yes, they are.

Davis allows himself a wry smile and then walks to a rough-wood bar at the far end of the … jungle, I guess, pulls out a bottle, and pours me a glass. “That’s our new Navy rum,” he says. But he seems a little distracted. He starts tapping at his smartphone screen. Most—but not all—of the faux candles brighten and dim at his command. “It’s buggy as shit,” Davis says. He excuses himself and slips behind another set of curtains.

I sip rum as I try to figure out how he has pulled together this Las Vegas–caliber fakery in the two short months since he and his girlfriend-slash-business-partner, Joanne Haruta, signed the lease. Lost Spirits rum has won medals in spirits competitions, and deservedly so. It’s good. But as I drink, I consider another question: What the hell?

Before I can arrive at an answer, I detect something moving, something substantial creeping at a pace slower than a walk. Through the dim candlelight I see a pair of golden Egyptian sphinxes, each a couple of feet high, mounted on the front of what appears to be a barge that is soundlessly floating down what I now realize is an elevated canal. Then I see Davis, standing amidships like a vanquishing explorer.

He invites me aboard, but I’m already scrambling a few steps up to the boat, using the flashlight on my smartphone to see what is going on. The “canal,” it turns out, is a 3-foot-high, elongated water tank—it holds 5,000 gallons and runs the length of the building, cooling the fermentors and the still. Davis built the barge, which seats about eight, to travel up and down the distillery. He tells me to put away my phone—I’m ruining the illusion!—and take a seat.

We slowly start down the waterway. “You know the Pirates of the Caribbean ride at Disney?” Davis says. “You can’t just get off and drink with the pirates. That’s the problem we were trying to solve.”

Well, one of the problems. The other, which had brought me here to meet with Davis in the first place, has more to do with chemistry than with theater. The rum I’d just sampled tasted like it had spent at least a generation in a barrel. It had actually been aged only six days. “We’re throwing all the tools you’d use for curing cancer at making a mai tai,” Davis says.

Davis “aged” that rum in a high tech reactor of his own invention, which uses heat and light to try to do in a week what might otherwise take decades. He isn’t the first to try to find this Northwest Passage of booze; Davis is the latest in a long line of inventors, beverage chemists, and flimflam artists who have claimed to find ways to cheat time.

But his approach is different—at least according to Davis. His patented reactor sits in a room just ahead, so we float slowly, very slowly, on an unseen stream into an inexplicable heart of dorkness.

“We’re throwing all the tools you’d use for curing cancer at making a mai tai,” Davis says. Photo © Joe Pugliese

There’s a simple way and a complicated way of thinking about distilled spirits in a barrel. The simple way is to think of a barrel like an inside-out tea bag. The wood of a barrel—they’re almost always made of white oak—contains compounds that taste good when they degrade, especially when the interior has been toasted or charred. The lignin, hemicellulose, and other polymers that give the wood structure break down to produce sweet, vanilla notes. Alcohol is an efficient solvent, so it seeps into the wood and captures these compounds.

The complicated way to look at maturation is through organic chemistry. Yes, an alcohol solution extracts flavor from the broken-down wood. But slower, more elaborate chemical reactions also happen among the esters and acids in unaged liquor. A barrel sitting silently in a dark warehouse doesn’t look like it’s doing anything, but that’s deceptive. Over months and years, compounds decompose and recombine in dozens of different ways—with the chemicals leached from the oak, with oxygen that enters between the barrel’s staves, and with the ethanol itself.

So you might start with traces of something like butyric acid. It’s not an especially desirable flavor—it’s partly responsible for the vomity smell you can detect in Parmesan cheese. But when it combines with ethanol, it forms ethyl butyrate, which smells like ripe pineapple. Skilled distillers have even learned to tweak the process to encourage some of these elements and discourage others. In Jamaica, for instance, rum makers often add fast-reproducing microbes to their fermenting mash. Yeast cells, competing with these microbes for sugar, produce acids to fight them—but during aging, those acids also react with alcohol to create new compounds. Their fruity, weird flavors are part of what makes Jamaican rum so big and funky and delicious.

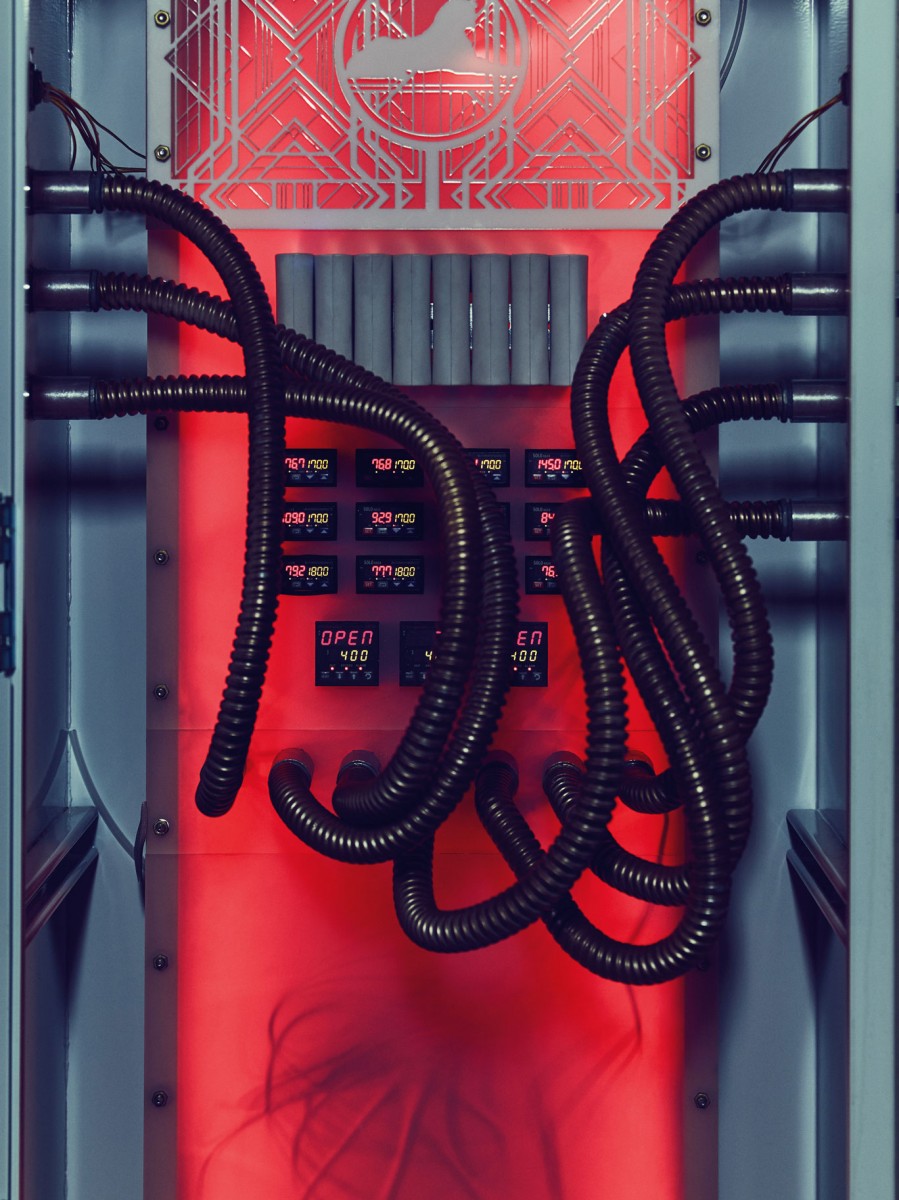

Inside the brains of the booze-aging reactor. Photo © Joe Pugliese

All this happens naturally and over time. It’s the job of a distiller to find the ideal moment to bottle the booze, when the chemical reactions that make good flavors have taken place but before the flavor of the wood itself takes over and becomes too bossy. “Everything we’ve ever done says you cannot shortchange the double decomposition that goes on,” says Mark Brown, president and CEO of Sazerac, which makes bourbons including Buffalo Trace and cult favorite Pappy Van Winkle. “There’s this really peculiar thing that goes on over time that only time can deal with.” For bourbon, Brown says, eight to 10 years is the sweet spot.

But time is literally money when it comes to aging spirits. A single standard oak barrel sets distillers back $150 or more, and that’s only a down payment. They still need to store the barrels in expensive warehouses that require maintenance and incur taxes. Being semiporous, barrels lose some of their content, often around 5 percent a year, through evaporation. What’s more, the spirit inside that barrel has already consumed capital—in the form of raw materials, pricey distillation equipment, and the salary of a distiller. And then it just sits there, mocking investors by producing no immediate tangible return.

It’s without doubt one of the more idiotic business models ever devised, in no small part because supply and demand are wholly asynchronous. Consumers today clamor for quality aged bourbon, which would be really good news for distillers if only they had a time machine and could travel back five or 10 years and ramp up production.

“You know the Pirates of the Caribbean ride at Disney?” Davis says. “You can’t just get off and drink with the pirates. That’s the problem we were trying to solve.” Photo © Joe Pugliese

Yet somehow that business model is not so idiotic that it keeps people out of the industry. In the past decade the US has gone from a few dozen craft distillers to well over a thousand. This has led to an age of experimentation, as the slew of newcomers scramble to move quality aged spirits more swiftly from still to shelf.

Many simply use smaller barrels—instead of the industry standard, 53 gallons, they use casks that hold between 5 and 30 gallons. With that increase in the ratio of wood to liquor, the alcohol takes on more barrel flavor more quickly. But the brief interlude shortchanges long-term reactions, which can often mean that a whiskey distiller will end up bottling something that’s nice and oaky but also plagued with a sort of cornflakes aroma.

Distillers have tried many clever tricks to speed up those advanced reactions. Tuthilltown in Gardiner, New York, and Copper & Kings in Louisville, Kentucky, have employed sonic aging—blasting barrels with high-volume music, especially heavy on the bass, to prod the contents to move along. Others, like Jefferson’s Bourbon, with its Ocean label, have put casks on sea-voyaging ships, thinking the constant rocking and sloshing will accelerate reactions. I recently tasted a sample of Jefferson’s that had been “aged” in this manner, in casks aboard a boat, down the Mississippi River from Kentucky to New Orleans. It was good, but the method probably doesn’t scale. Rocking—literally or acoustically—at present appears to make more sense for marketing than for production.

When Davis started experimenting with fast-aging liquor, he tracked down a bottle of superb 33-year-old rum from Guyana and sent it to a lab for chemical analysis. The gas chromatography/mass spectrometry results he got back gave him a rough outline of the rum’s molecular fingerprint, a breakdown of what decades of aging had created. The results showed prominent spikes of ethyl dodecanoate, sinapaldehyde, and other compounds that had formed over time. Davis set out to forge that fingerprint.

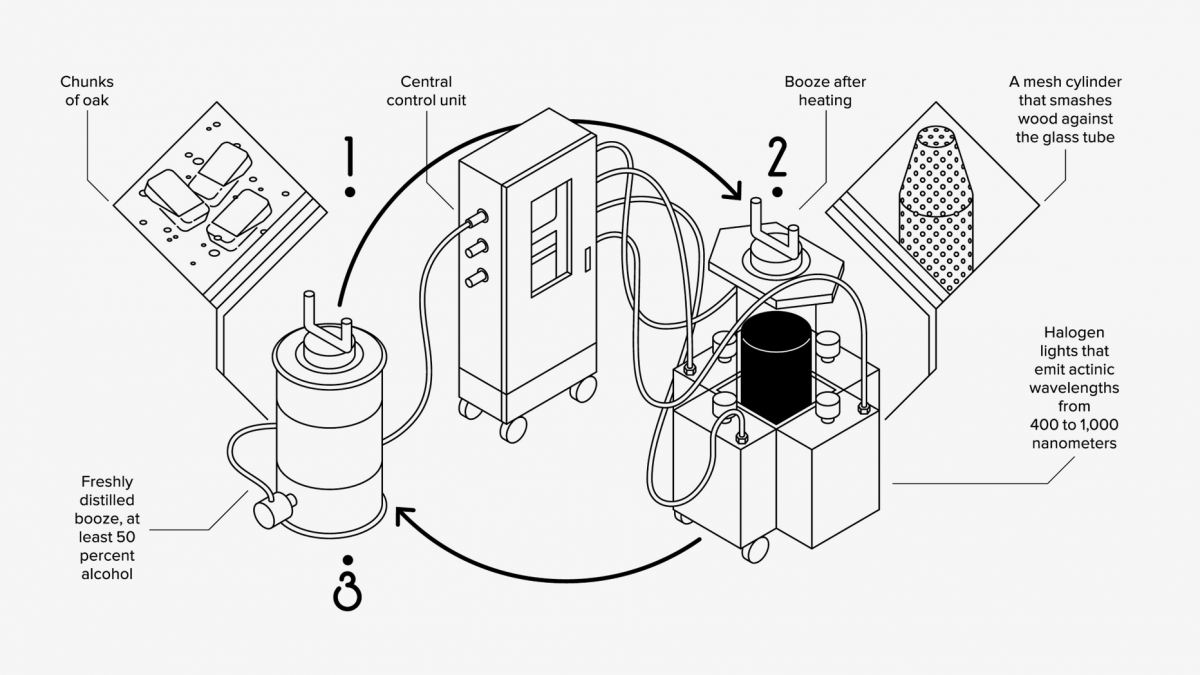

Liquor Quicker

As a cult-favorite craft distiller, Bryan Davis has been experimenting for more than a decade with ways to make young booze taste old—or at least weird. Now Davis says he has a contraption that can make rum or whiskey seem like it has spent 20 years in a barrel after just a few days. It might even work.

Unaged booze and wood are combined in the tank and heated at a temperature between 140 and 170 degrees Fahrenheit for several days. Acids in the wood help turn volatile molecules created during fermentation into flavorful esters.

The mixture flows into a glass cylinder, where light breaks down polymers in the wood. That releases more flavorful molecules and a few things you don’t want, like medium-chain acids and precursors to ethyl acetate—basically nail polish remover.

Back in the tank for more heating, the complex solution undergoes further reactions. The acids convert to esters that in turn bond to other molecules, resulting in compounds with rich, honeylike notes identical to those formed by long-term aging.

Davis is slightly stocky and has a shaved head. From across the room he can look like Mike Myers playing Dr. Evil. When he gets excited, which is often, particularly if you introduce a subject like the eons-long war between microbes and yeast, his eyes flare. Sometimes this seems like a visual exclamation point to accent his comments; other times it has me wishing for a foil hat to prevent a secret force field from taking over my controls. He can be very convincing.

Davis grew up in the central-California hills between Monterey and Salinas. When he was in high school, he built his first still—an empty whiskey bottle, a hot plate, some copper tubing, and a 5-gallon cooling bucket. The nasty rum he made from white sugar was good enough to enhance his status among thirsty fellow students. While studying sculpture at the San Francisco Art Institute, Davis started dabbling in making absinthe, which was emerging from a decades-long nap. It was better than his rum, and he found it to be a useful offering for rides on art cars at Burning Man. After graduation Davis worked for a design firm making elaborate faux environments at theme parks and malls. If you’ve ever been to Grizzly Gulch at the San Francisco Zoo, you’ve seen the work of Bryan Davis.

Davis and Haruta started dating when he was 21. Four years later they moved to Spain to make absinthe, which was then legal in Europe but not yet in the United States. They ended up in Lleida, a city two hours outside Barcelona, where they leased a building, grappled with arcane regulations in a language they didn’t speak, and built and operated their own still, producing and selling Obsello absinthe and Port of Barcelona gin.

Getting a distillery up and running was a daunting task, but after spending some time with them, it’s not hard to imagine how they pulled it off. Davis and Haruta are a sort of bookend couple: Davis seems to do most of the talking and idea mongering, with Haruta from time to time interjecting with a recap—with more context and a less-staccato delivery. She seems to be the one who anticipates complications before they arise, a center of gravity for Davis’ flights of fancy.

Davis imports young whisky from Scotland but makes his own Lost Spirits Navy rum from molasses. Photo © Joe Pugliese

Their absinthe and gin proved a solid if not raging success. After nearly five years abroad, Davis and Haruta decided to head home. They set up shop on some land Haruta’s parents owned near Salinas and built a new distillery for $80,000, including an outdoor still that vented steam through a metal dragon’s head. They first produced a peated whiskey. But after early experiments in speeding up the formation of esters by adding wood chips to the casks, they switched to rum—which they’d started making only as an agent to season barrels before putting whiskey in.

Davis didn’t stop tinkering. He read that early distillers sometimes add banana and jackfruit into fermenting rum to introduce microbes, so in Salinas he started cultivating bacteria on bananas and adding it to the mash. He began infusing oak into spirits, steeping it in various forms and at various temperatures, to see if he could coax out better flavors.

The Newton-and-the-apple moment came one afternoon in 2013. “I was walking out to the still and thought, ‘Geez, I need to repaint my deck,’” Davis says. “I got about a hundred yards, and I thought, ‘Wait a minute.’ So I ran back and looked at the deck again.” The wood was cracked and splitting. The relentless California sunlight was doing just what alcohol does to a barrel—breaking down polymers that give wood its structure—but the sun was doing it pretty efficiently. “If we re-created this effect, but with the wood inside a tube filled with booze, all those degradation byproducts would get trapped in the liquid,” he realised…

Read the rest at Wired

Like this? Here’s a bourbon that’s aged at sea

Like this? Wash-up coke labels are used for sustainable rum labels

You might be interested in...

GRAIN & GRAPE

Auchentoshan Breaks New Terroir With Their Limited Edition Sauvignon Blanc-finished Expression

DRINK HERE: LIME HOUSE (EAST COAST)

Get Liming on The East Coast With The Caribbean Bar and Restaurant's Newest Home.

GLEN GRANT 60 YEAR OLD

Worth the Wait.

GRAIN & GRAPE

DRINK HERE: LIME HOUSE (EAST COAST)

GLEN GRANT 60 YEAR OLD